How to Select Injection Molding Services in China

So, the big meeting just wrapped up. your new product is a go, the schedule is tight, and the budget is, let’s say, constrained.. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

Naturally, you agree. It seems sensible at first glance. The potential savings can be massive. Yet your thoughts are already spinning. You’ve heard all the horror stories, right? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It can feel like you’re being asked to walk a tightrope between landing a huge cost win for the company and steering your project straight into a ditch.

But here’s the catch. Procuring plastic mold needn’t be a roll of the dice. It’s simply another project with clear steps. And as with any project, success depends on your methodology. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Forget the horror stories. Here’s a practical playbook to nail it.

Initial Step: Prepare Your Information

Before you mention “supplier” or browse Alibaba, organize your internal data. Truthfully, over fifty percent of offshore sourcing issues originate in an unclear project brief. Don’t assume a remote factory can guess your needs. A vague RFQ is like telling a contractor to bid on “a house.” You’ll get wildly varied quotes that are useless.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. It’s the cornerstone of your entire effort.

What belongs in your RFQ?

Start with your 3D design files. They cannot be skipped. Use standard formats such as STEP or IGS to ensure compatibility. This is the master blueprint for your part’s geometry.

Yet 3D models don’t cover everything. Include precise 2D engineering drawings. This is where you call out the stuff that a 3D model can’t communicate. Think tolerances, material grades, finish specs, and any feature-critical notes. Any seal surfaces or critical hole sizes must be clearly labeled.

After that, material choice. Don’t just say “Plastic.” Even “ABS” alone is too vague. Be explicit. Call out SABIC Cycolac MG38 (black), for example. What’s the reason? Because there are thousands of plastic variations. Defining the exact material guarantees the performance and appearance you designed with what is plastic mold.

They can offer alternatives, but you must provide the initial spec.

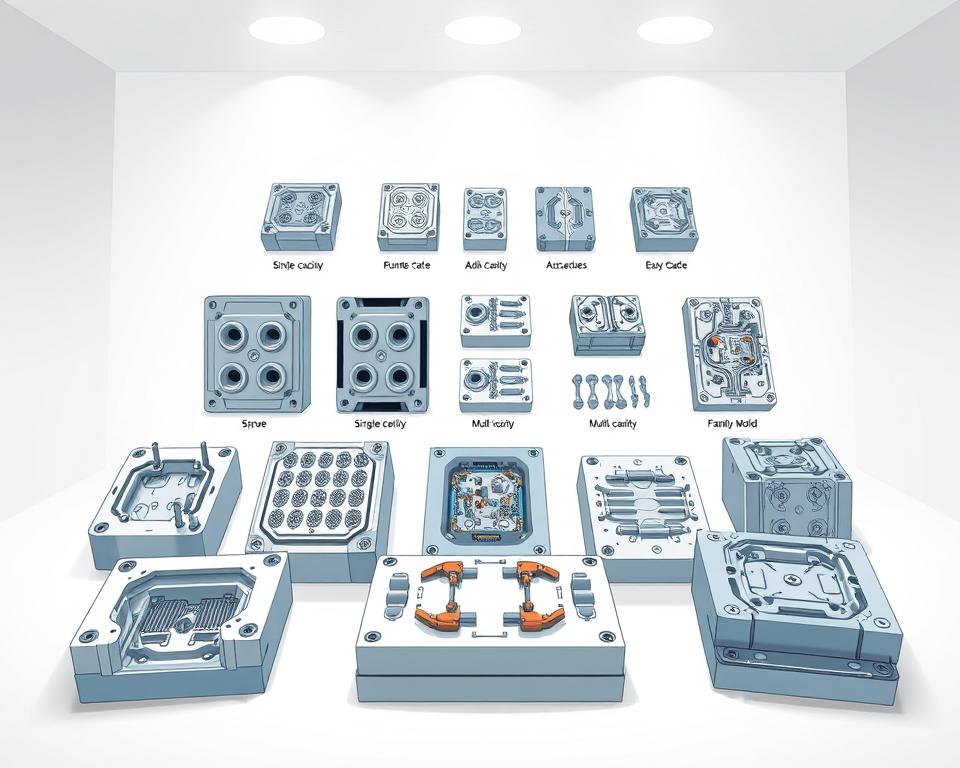

Lastly, add your business data. State your EAU. You must specify if it’s a 1K-part tool or a 1M-part production run. Cavity count, tooling cost, and per-unit pricing depend on volume.

Finding the Right Supplier

Now that your RFQ is pristine. who gets your RFQ? The internet has made the world smaller, but it’s also made it a lot noisier. Locating vendors is easy; vetting them is the real challenge.

Your search will likely start on platforms like Alibaba or Made-in-China.com. They let you survey dozens of suppliers quickly. But think of them as a starting point, not the finish line. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

However, don’t end your search there. Think about engaging a sourcing agent. Yes, they take a cut. Yet top agents deliver reliable, audited suppliers. They bridge language and cultural gaps. On your first run, this is like insurance. It’s schedule protection.

Also consider trade fairs. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. In-person meetings trump emails. Inspect prototypes, interview engineers, and sense their capabilities. And don’t forget the oldest trick in the book: referrals. Tap your professional contacts. A recommendation from a trusted peer is often worth its weight in gold.

Separating Real Suppliers from Pretenders

With your RFQ dispatched to dozens of firms, estimates roll in. Some will be shockingly low, others surprisingly high. Your job now is to vet these companies and narrow it down to two or three serious contenders.

How to proceed? It’s a bit of an art and a science.

Step one: audit communication. Do they respond quickly and clearly? Do they communicate effectively in English? But here’s the real test: Are they asking you intelligent questions? A great supplier will review your RFQ and come back with thoughts. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” This is a massive green flag. You know they know their stuff. Anyone who simply agrees to all specs is a red flag.

Next, dig into their technical capabilities. Get their tooling inventory. Seek samples or case studies of comparable projects. A small-gear shop won’t cut it for a big housing.

Finally, inspect the factory. Skipping this is a mistake. As you vet staff, you must vet suppliers. Either visit in person or engage a local audit service. They perform a one-day factory inspection. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. It’s a tiny cost for huge peace of mind.

From Digital File to Physical Part

After picking your vendor, you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Now the process kicks off.

Your supplier’s first deliverable is a DFM analysis. DFM stands for Design for Manufacturability. This is your supplier’s formal feedback on your part design. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. A thorough DFM is a sign of a professional operation. It’s a two-way partnership. Together, you tweak the design for best manufacturability.

With DFM sign-off, toolmaking begins. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are the very first parts off the new tool. It’s your first real test.

Be prepared: T1 samples are almost never perfect. It’s par for the course. There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold in China samples. This process might take a couple of rounds. Build buffer time for sample iterations.

Eventually, you will receive a part that is perfect. Dimensions, finish, and performance all check out. This is your golden sample. You ratify it, and it becomes the quality yardstick for production.

Crossing the Finish Line

Getting that golden sample feels like the end, but it isn’t. Now you’re entering the mass production phase. How do you ensure that the 10,000th part is just as good as the golden sample?

You need a clear Quality Control plan. Often, you hire a pre-shipment inspection service. Again, you can hire a third-party service. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. They’ll send you a detailed report with photos and measurements. Once you sign off, you greenlight shipping and the last payment. This simple step prevents you from receiving a container full of scrap metal.

Lastly, plan logistics. Clarify your Incoterms. Does FOB apply, passing risk at the ship’s rail? Or EXW, shifting all transport to you? These details have a big impact on your final landed cost.

Overseas sourcing is a marathon. It’s about building a relationship with your supplier. See them as collaborators, not vendors. Transparent dialogue, respect, and process discipline win. Certainly, it’s complex. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’re set to succeed.